3 Things to Consider when Choosing Energy Efficient Windows

Categories: Windows + Doors

Are you done with having your money fly out of the window?

The U.S. Department of Energy estimates that heat transfer through your windows is responsible for 25-30% of residential heating and cooling energy use. This is no small amount considering that the average home spends approximately $1100 annually on these costs. If you have a home with older windows heating costs can be even higher due to outdated manufacturing practices.

Often, replacing your windows is your best bet to get the most efficiency out of them. However, with so many different configurations and industry terms out there it can be hard to know what’s best.

When you select new windows, there are three main factors that influence energy efficiency. These factors are:

- Frame Material

- Glass Features (e.g. glazing, insulation)

- Spacing and Gas Fills

We’ve put together this guide to help you select the right configuration for your windows.

1. Frame Material

There are a number of different options to consider when choosing the right frame material for your energy efficient home. Though there are some frames which are more energy efficient than others, there are still certain trade-offs which exist between each type. When choosing your own frame, it’s important for you to consider what fits in best with your environment, budget and overall aesthetic goals.

Frame material comes into consideration when looking at resilience to changing temperatures. Temperature swings can cause expansion and contraction of both the glass and frame. The degree a material expands or contracts is called the thermal expansion coefficient.

Since different materials expand at different rates, dramatic temperature changes over time can cause small leaks between the glass and the frame. Materials with an expansion coefficient closer to that of glass are ideal for minimizing the impact of this. Marvin’s Ultrex (Fiberglass) Guide compares the expansion coefficients of common frame materials to glass. This graphic from This Old House summarizes the key metrics between each window material.

Fiberglass:

Fiberglass frames are a perfect choice if you are interested in something durable, water-resistant and energy efficient. Extremely rigid in nature, fiberglass window frames do not change form with the weather and can prevent a large amount of heat from transferring through them. Nonetheless, fiberglass frames are still less rigid than aluminum frames and transfer more heat than wood or vinyl frames. Bearing this in mind, they are a great option if you are looking for a happy medium between aluminum and wood frames.

Wood Frame:

A timeless classic, wood frames are adored by many different types of homeowners. Stylistically, wood frames have a beautiful aesthetic to them. Moreover, when constructed properly, wood frames only look better as they age. Wood frames are also a strong option because they can last for decades (even centuries) when built well. Finally, and most importantly, wood frames are energy efficient. In fact, out of all the frame types we’ll be discussing, wood frames have been found to have the best insulation.

So, bearing all of these factors in mind, this begs the question: “Why doesn’t everyone have wood frames?” Unfortunately, wood frames also have drawbacks to them, mainly in terms of pricing and water resistance. Well-constructed wood frames tend to be more expensive than vinyl frames and require periodic maintenance to prevent mold and warping.

Vinyl Frame:

Vinyl window frames are a great way to go if you are looking to stay at a lower-budget. Vinyl frames are not prone to the same maintenance issues as wood, making them perfect as a low-maintenance alternative.

One of the main issues with vinyl is its high rate of thermal expansion. This makes openings between the glass and frame likely over time.

Aluminum:

Aluminum windows are valued for their high durability. Unfortunately, aluminum window frames are not ideal for energy efficiency. With aluminum window frames, heat can be conducted very rapidly. This makes them a poor fit for insulation.

However, aluminum frames are often built with thermal breaks to help compensate for the high conductivity and poor energy efficiency of the material.

2. Glass Features

The specific glass used in windows is extremely important in ensuring energy efficiency in your home. Though many may think that the glass in a window is simply just glass, this couldn’t be further from the truth. As a matter of fact, it is one of the most complex features in any window. From its quality to its coating, there are many of factors to take into account when deciding on which features you want your glass to have.

Before we dive into the details on what makes window panes energy efficient, let’s define some key industry terms.

Energy Efficient Glass Terminology

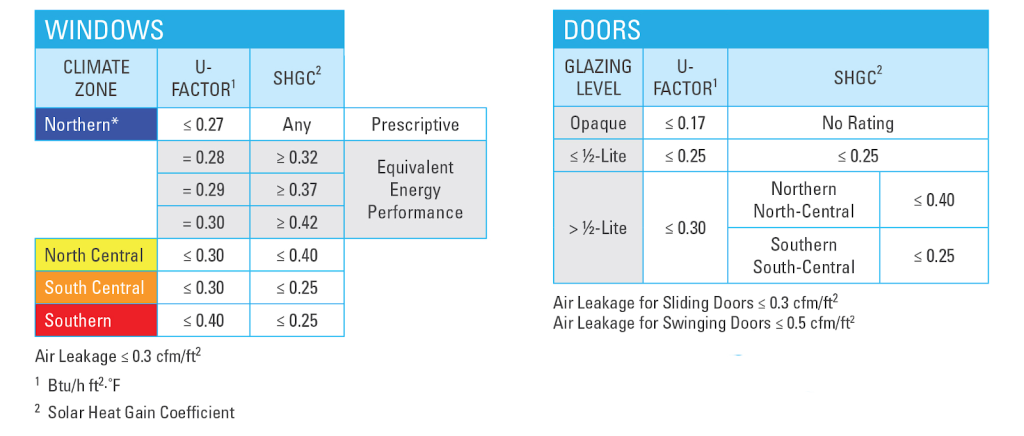

Energy Star Window Qualification Criteria (USA)

U-Factor:

A window’s U-Factor measures the rate of heat transfer and tells you how well the window insulates. In terms of energy efficiency, this means that the lower the U-factor for a window is, the more efficient it is.

Solar Heat Gain Coefficient (SHGC):

The SHGC of a window describes how well a window heats up from the sun. It is typically more energy efficient to have a low SHGC so less energy is placed towards cooling your home. This is especially important in warmer climates (not so much here in MA) and in homes that do not have a lot of shading.

Visible Transmittance (VT) Rating:

The VT rating of a window measures the amount of light it allows to pass through it. A higher VT rating is ideal as this allows more natural light to shine through your window and into your home.

Energy Efficient Glass Coatings

Insulated:

Insulated windows achieve their insulation through being built with two or more panes of glass. Through using multiple panes of glass an airtight seal is created, making any window extremely insulated.

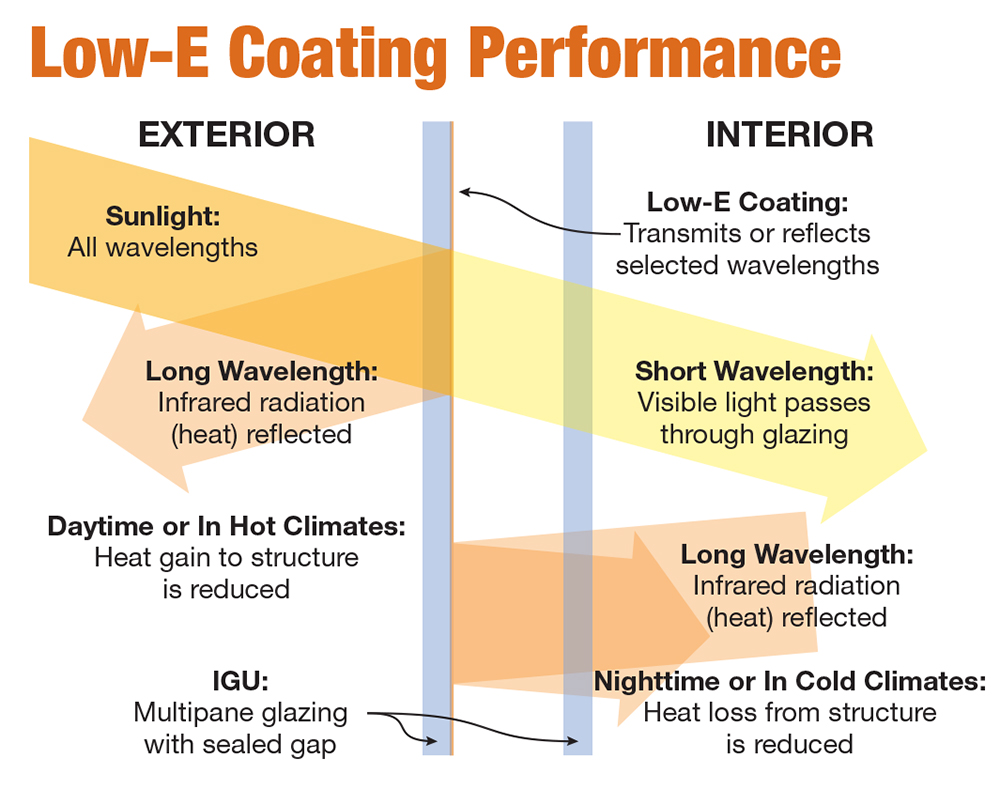

Low-Emissivity Coating:

Low-emissivity coating in a window’s glass creates insulation through a glaze that is combined with multiple panes of glass. Though low-emissivity coating tends to cost 10-15% more than other methods of glass insulation, it also reduces energy loss by 30-50%. This is extremely important from an energy efficiency perspective as well as an economic one.

In addition to the economic and efficiency-related benefits of low-emissivity coating, it is also nearly invisible and leaves room for a great aesthetic as well. Diving into the more specific aspects of low-emissivity coating, it has a lower U-Factor and tends to reduce the VT of your windows. Another great benefit of low-emissivity coating is that you can apply it yourself at a fairly low cost and it will last for the next 10-15 years.

3. Gas Fills

Another method of increasing the efficiency of your windows is to focus on what goes between the panes of glass. We can maximize energy efficiency by filling the inside of the windows with different types of gases.

Gas fills are used to minimize heat transfer from the interior of a window to its exterior. The two most common gases used are air and argon. Argon is a colorless, non-toxic gas that conducts heat poorly. This makes it a great choice for insulating your home. All windows with multiple panes have some kind of gas fill but argon is a more efficient choice.

Considering these features before choosing your next windows will make the route to energy efficiency easier than ever. If you need more guidance, click below and download our window comparison guide. This guide will help you easily identify which windows best suit your needs.